With the MAOF Carcass Disposal System, you’ll avoid the hassle of composting and the risk of third parties coming to your site. Instead, you’ll save time and money by taking mortality management into your own hands.

All you need to do is load the machine and start the cycle.

The carcasses will be heated and mixed to break down bones and feathers sterilizing the contents. The contents are dried to your desired level of dehydration, then transferred to the storage bin.

And what’s left? A sterile, organic, flour-like byproduct that’s perfect for use in compost or fertilizer.

THE EJECTION SCREW

A maintenance free screw system, will propel the “MEAT POWDER” out of the drying chamber, and eject it into a bag or container. The operator can control the time of the screw operation and stop the process to move and replace the storage container/bag. Typically, a 15 minute screw operation time is sufficient to empty the drying chamber. It is critical that the drying chamber is completely empty at the end of a cycle.

THE BYPRODUCTS- “MEAT POWDER”

Alternatives for the use of the byproducts produced by the system. As the resultant “meat powder” is a stable, odor free, sterile byproduct it can be field applied, integrated into commercial fertilizer or utilized in commercial processing. Most farmers are selling it for the production of commercial fertilizer. Additional evaluation into its use as a high crude protein feedstuff is anticipated.

TESTING & APPROVALS

The approval process included in-depth, long-term analysis of the effectiveness of the thermal dehydration process, aerial emissions and environmental impact of thermal dehydration of poultry mortalities.

These efforts have determined that there are no visible emissions from the thermal dehydration unit, other than water vapor. Volatile organic compounds (VOC) emissions are only minimally elevated from the exhaust stack compared to background VOC levels during operation.

The resultant “meat powder” is a stable, odor free, sterile byproduct which can be field applied, integrated into commercial fertilizer or utilized in commercial processing. Compositional analysis has consistently demonstrated a moisture content of approximately 20%, with Nitrogen level of approximately 10%, Phosphorus of 0.5% and Potassium of 0.6%. This is equivalent to a commercial fertilizer providing approximately 160 lbs. of N per ton when applied directly to the field (wet basis).

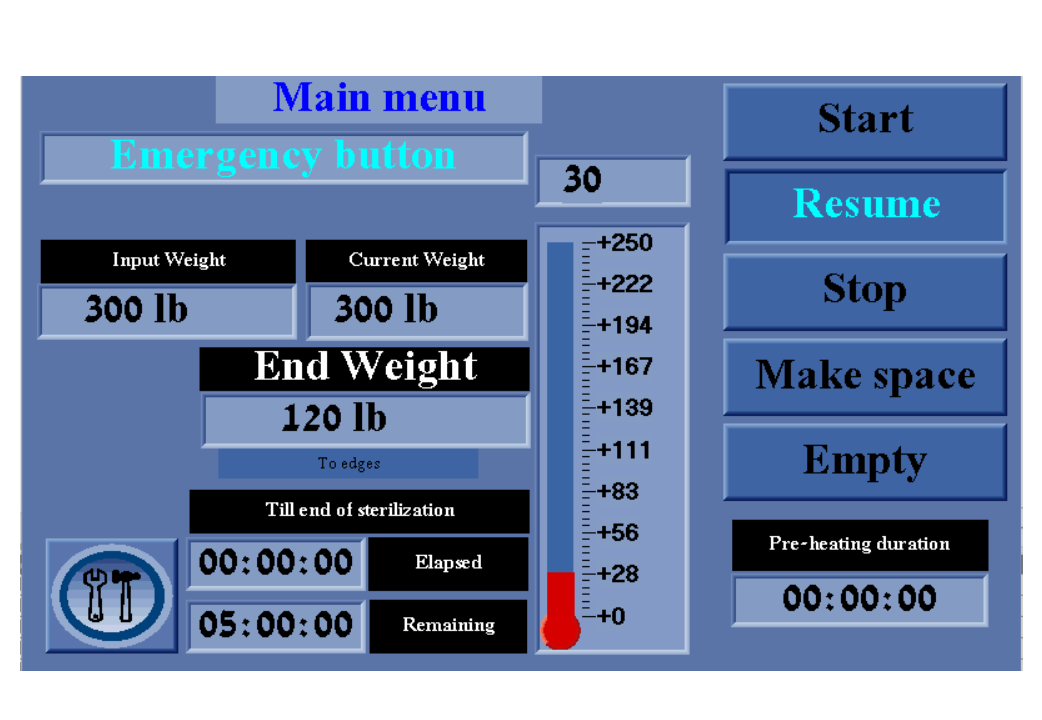

PROCESS CONTROL

The system is computerized and controlled. Registered and controlled data (temperature and weight). Different operating programs depending on the carcasses weight. Features include: power saving in night operation. remote activation (optional) , fault reporting.

SAFETY

Numerous safety features have been included in the design to protect all workers. The design engineers, who are also farmers, are aware that youth are often operating farm machinery. One critical safety feature is the stop motor safety switch, which ensures that there are no moving components when the carcass loading door is opened.

The loading door is always at the optimal height for loading- irrespective of the size of the model.

PROCESS AUTOMATION

Manual labor is only required to load the carcasses. The system is fully automated. The system cannot be operated if the loading door is not shut securely. For the purpose of our promotional videos, the engineers bypassed the safety lock on the loading door. The bypass cannot be implemented in the machines supplied to clients.